The methods procedures for manufacturing 5052 aluminum plate:

The process of turning aluminium and its alloy into sheet or coil with rectangular cross-section through smelting, ingot casting, various pre-rolling preparations, flat roll rolling, heat treatment and finishing.

1. Aluminum and aluminium alloy sheet strips are supplied in hot rolling, annealing, various grades of soft state and various heat treatment states.

2. Preparation before hot rolling mainly includes casting quality inspection, heat treatment, sawing, milling, aluminum cladding and heating.

3. In semi-continuous casting, the cooling rate is very high, the diffusion process in solid phase is difficult, and the chemical composition and structure of ingot are uneven, such as intragranular segregation, which reduces the plasticity.

4. When there are defects such as segregation, floatation, slag inclusion, scarring and crack on the surface of ingot, milling surface (see milling surface of non-ferrous metal alloy ingot) should be carried out, which is an important factor to ensure good surface quality of finished product.

5, hot aluminum alloy ingot is provided for cold rolling plate blank, or direct the production of hot rolled state.

6, hot rolling process system includes pass reduction rate, rolling temperature, rolling speed and lubrication cooling.

Material1000series:1435,1050,1060,1070,1080,1100,etc

2000series:2011,2014,2017,2024,etc

3000series:3002,3003,3104,3204,3030,etc

5000series:5005,5025,5052,5040,5056,5083,etc

6000series:6101,6003,6061,6063,6020,6201,6262,6082,etc

7000series:7003,7005,7050,7075,etc

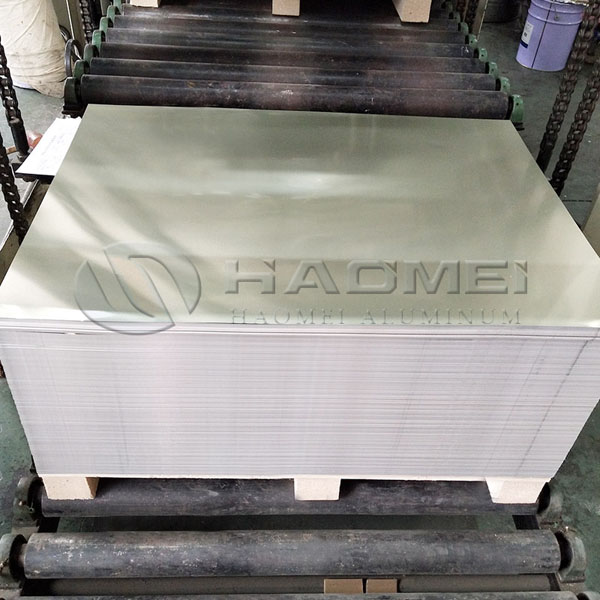

We offer a variety of alloys,in a range of standard sizes and thicknesses. We can provide custom cut-to-size aluminum sheet metal to meet your exact requirements.

We also offer embossed, rigidized, and textured aluminum sheet metal for specialized applications.