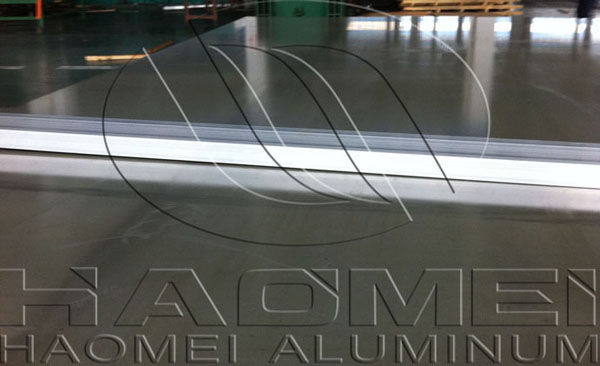

Aluminum precision plate in the humid air, water or other electrolytes, under the action of surface are vulnerable to corrosion and deterioration, serious when will become a waste.In order to prevent aluminium plate in the process of long distance transportation and storage for a long time suffer from corrosion, according to the requirements of technical conditions, some aluminum plate before packing to deliver goods, first on both sides of the aluminum plate coated with anti-rust oil.

Aluminum brazing plate sheet is often used as 7005 rust proof oil or industrial petrolatum and machine oil as antirust oil for packaging. The main requirements of antirust oil is oily itself contains water and impurities should comply with the relevant standards and regulations; oil acid, alkalinity should be appropriate; it has no corrosion on the aluminum plate surface; stable chemical performance of antirust oil itself, not bad, not failure in the process of long-term storage; when the oil is not volatile, to produce or pollute the environment harmful to human body harmful gases.

During the process of use, the moisture content in the oil should be analyzed from the oil tank every day, and the oil samples in the tank should be analyzed in a comprehensive way. When it is found that impurities, such as acid, alkalinity and moisture, do not meet the requirements of technical standard and operation rules, they should be replaced in time to ensure the quality and anti-corrosion effect of oil.

On both sides of hot rolled aluminum plate reservoir should be covered, the oil film should be uniform, but thick, but also thin.When your aluminum sheet parts not besmear oiling, you should take timely adjust oil roller clearance or roll changing, etc. Measures to solve them.